CPIT TL3 - Smart Factory

Smart Factory is a platform built in accordance with the principles of the Industry 4.0 concept. Smart Factory is a comprehensive, well equipped laboratory for teaching, demonstration, testing and experimental development of technologies used in the digitization of industry. Smart Factory is a space for academia to meet and cooperate with industrial partners. Smart Factory was built at VŠB-TU Ostrava within the project "Platform of new technologies FEI CPIT TL3", CZ.02.2.67/0.0/0.0/16_016/0002467 and launched in autumn 2020.

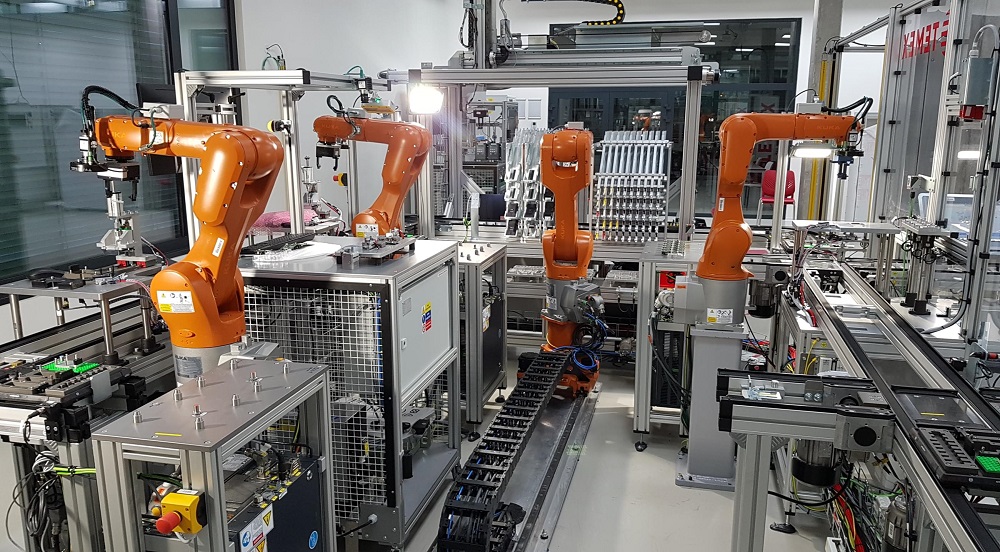

Smart Factory

The heart of Smart Factory is an assembly line equipped with industrial robots, a distributed control system based on PLCs, HMI / SCADA visualization systems. The line is extended by a comprehensive system for collecting process and diagnostic data. The assembly line is a comprehensive demonstrator of the use of the Industry 4.0 concept in industrial practice.

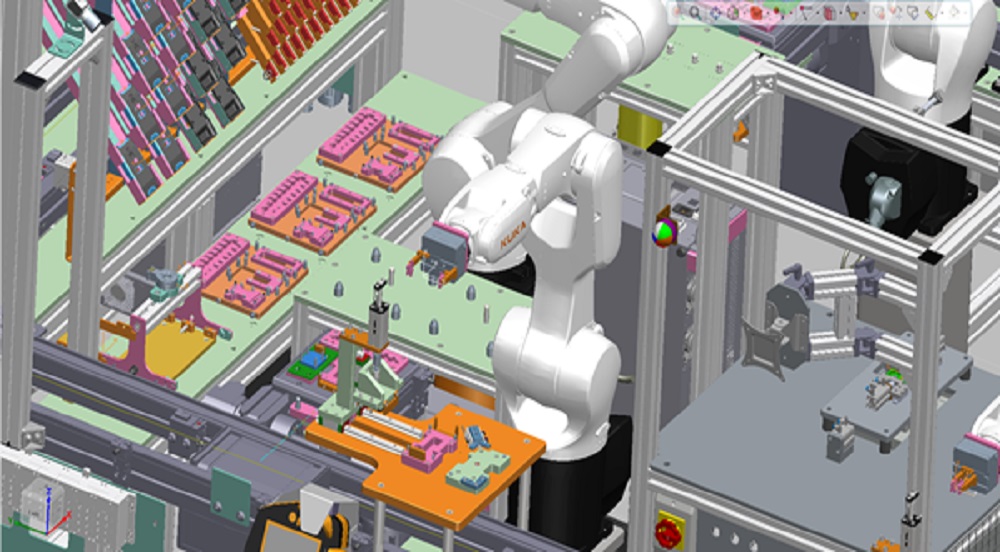

Digital twin

Smart Factory is built using virtualization technologies. In the first phase of the Smart Factory design, a complex virtual model of the assembly line and other parts was created. Such model is called a digital twin. This comprehensive model enabled testing and virtual commissioning before the individual parts of the Smart Factory were manufactured.

Virtual reality

Smart Factory can also be discovered and controlled using virtual reality. The different variants of the created digital twins allow you to enter the digital form of Smart Factory using virtual reality tools and discover it in detail.

Automation

Smart Factory is equipped by a control system in accordance with the latest trends in current automation. Distributed control system with many programmable controllers connected by Industrial Ethernet, visualization systems with operator panels and SCADA visualization workplace, extensive data repositories for process and diagnostic data.